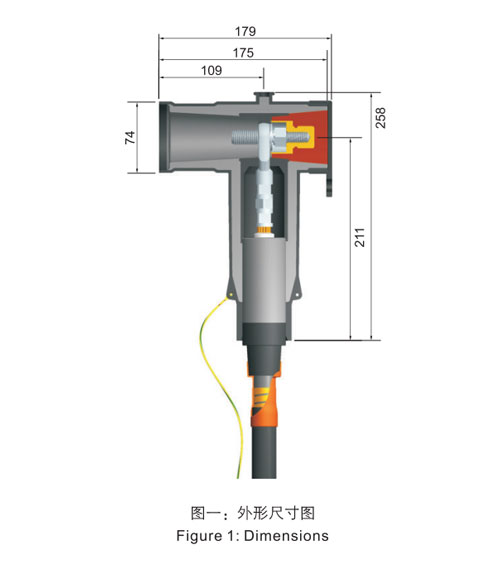

The JB 24-630A shielded cable connector, when used with the appropriate sleeve or plug, provides a fully shielded and fully submersible separable connection. Can be used as required by the specific situation. Built-in capacitance test point to determine circuit status or to install a fault indicator. No minimum phase gap requirement. Mounting can be vertical, horizontal or any angle in between.

System voltage up to 24 kV.

Continuous current 630 A (900 A overload for 8 hours).

Cable particulars:

- Polymeric cable (XLPE,EPR,etc.)

- Copper or aluminum conductors

-Semiconducting or metallic screens

- Conductor size 12kV 25-120mm² 24kV 25-400mm²

Provides a fully screened and fully submersible separable connection when mated with the proper bushing or plug.

Can be used under the circumstances

Built-in capacitive test point to determine the circuit status or install a fault indicator.

No minimum phase clearance requirements.

Mounting can be vertical, horizontal, or any angle in between.

Without any special tools

When finish the installation of elbow connector, the power can be supply directly.

According to the Installation Instruction Sheet (any other special requirement,please contact our salesengineer )

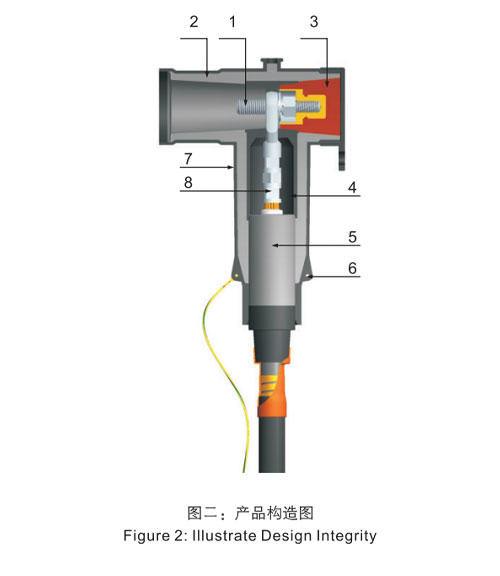

1. TWO HEAD SCREW: To make sure have a good contact with the apparatus bushing.

2. INSULATION: Moulded EPDM insulating rubber is formulated and mixed in-house to ensure high quality.

3. INSULATING PLUG: Molded epoxy insulating plug provides excellent electrical, thermal and mechanical reliability.

4. SEMI-CONDUCTIVE INSERT: Moulded EPDM conducting rubber screen controls electrical stress.

5. STRESSRELIEF:The configuration of the outer screen and the cable adapter provide cable stress relief.

6. GROUNDING EYE: Moulded into the external screen for connection of an earthing wire.

7. SEMI-CONDUCTIVE SHIELD: Moulded EPDM conducting rubber mates with the cable screen to maintain screen continuity and ensure that the assembly is at earth potential.

8. CONDUCTOR CABLE LUG: Aluminum compression connector is sized to ensure a cool running connector with maximum current transfer.

|

Reference No. |

Conductor cross section (mm²) |

Stretch range over insulation (mm) |

Cable Type |

Size of stress cone |

|

JB-24/630-35 |

35 |

18.6 |

12/20 |

B |

|

JB-24/630-50 |

50 |

19.6 |

12/20 |

B |

|

JB-24/630-70 |

70 |

21 |

12/20 |

B |

|

JB-24/630-95 |

95 |

22.6 |

12/20 |

C |

|

JB-24/630-120 |

120 |

24.2 |

12/20 |

C |

|

JB-24/630-150 |

150 |

25.6 |

12/20 |

C |

|

JB-24/630-185 |

185 |

27.2 |

12/20 |

D |

|

JB-24/630-240 |

240 |

28.7 |

12/20 |

E |

|

JB-24/630-300 |

300 |

31.1 |

12/20 |

E |

|

JB-24/630-400 |

400 |

33.2 |

12/20 |

B |

|

Reference No. |

Conductor cross section (mm²) |

Stretch range over insulation (mm) |

Cable Type |

Size of stress cone |

|

JB-25/630-50 |

50 |

26 |

18/20 |

D |

|

JB-25/630-70 |

70 |

27.6 |

18/20 |

D |

|

JB-25/630-95 |

95 |

29.2 |

18/20 |

E |

|

JB-25/630-120 |

120 |

30.6 |

18/20 |

E |

|

JB-25/630-150 |

150 |

32.2 |

18/20 |

E |

|

JB-25/630-185 |

185 |

33.7 |

18/20 |

F |

|

JB-25/630-240 |

240 |

36.1 |

18/20 |

F |

|

JB-25/630-300 |

300 |

38.2 |

18/20 |

D |

NOTE: The cable range is the basic element for choosing the product's type. The conductor size is just for a reference.

GET A QUOTE